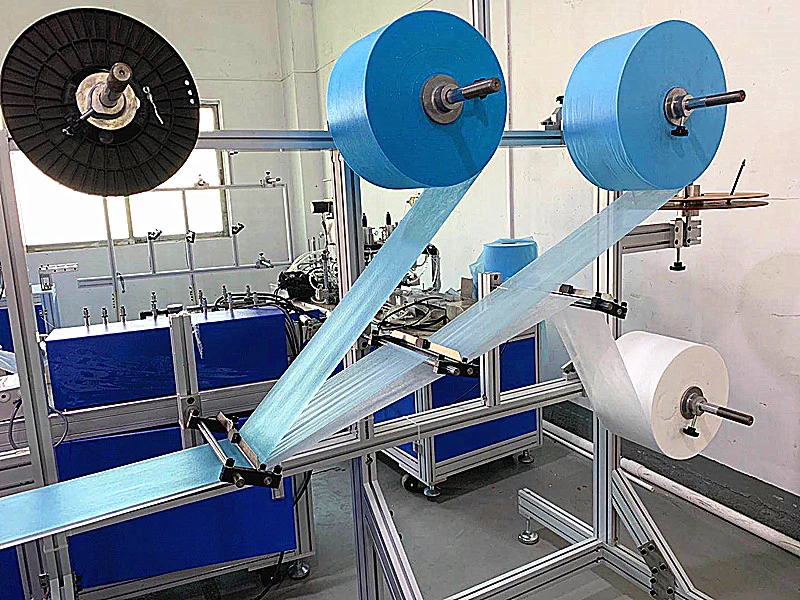

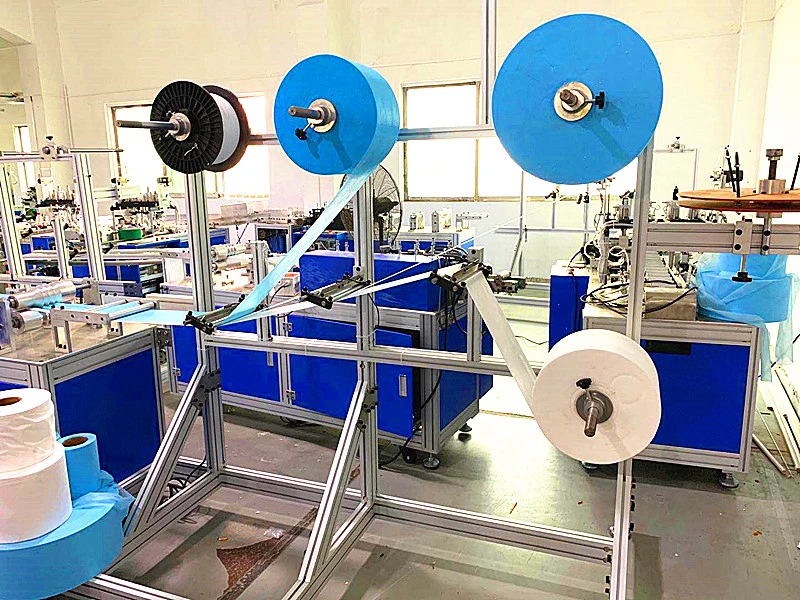

250PCS / Minute Fully Automated Disposable 3 Ply Flat Earloop Nonwoven Medical Surgical Face Mask Making Machine High Speed Mask Production Line

Machine Description :

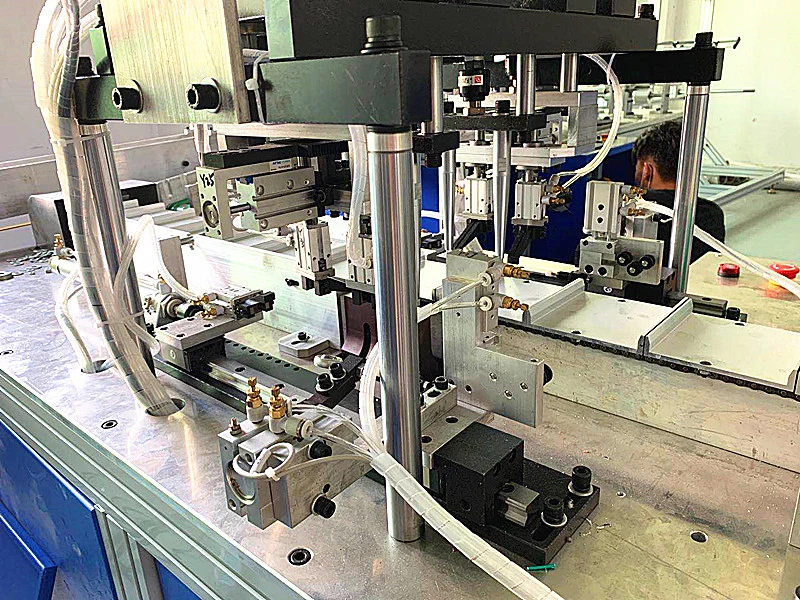

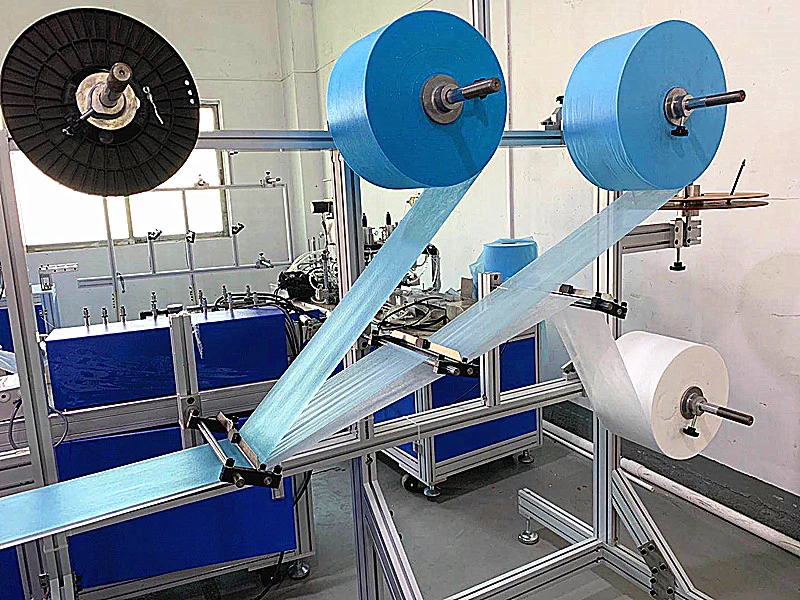

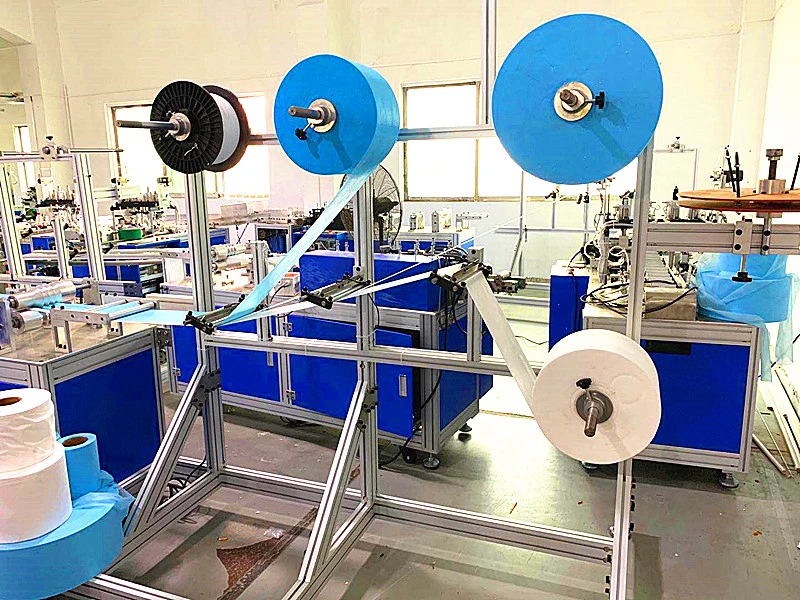

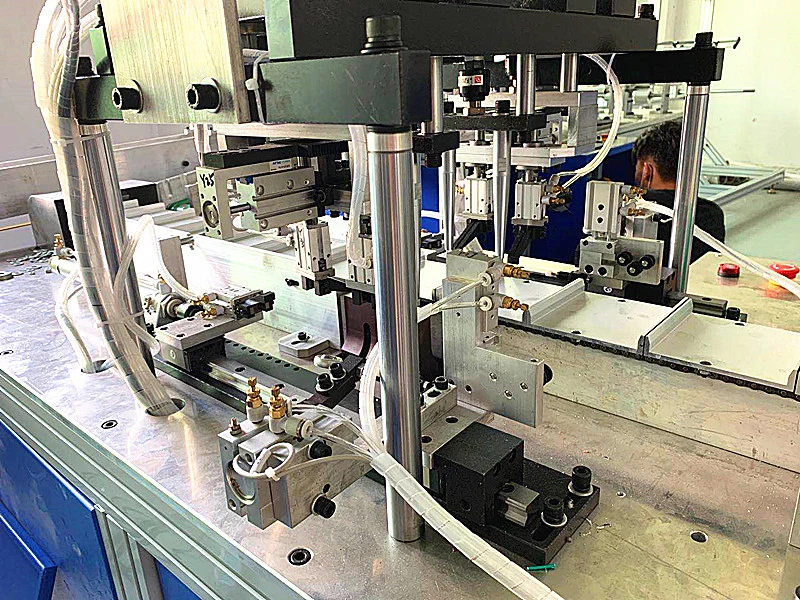

The mask making machine is used to fully automated make flat masks with size 175*95mm. The main production process flow is coil material feeding, nose bridge tendon feeding, folding and pressing, mask cutting and forming.Automatically completes production from raw materials to finished masks. The produced masks are comfortable to wear, no pressure, good filtering effect of the masks, fit the human face, and can be used in medical, electronics, mining, construction and other industries.

Basic Info. :

Service : English Video Call Installation Training

Product Type : Mask, Mouth Cover

Usage : Hospital, Public

Weight :600kg

Purpose: Making Disposable Face Mask

Driven Type : Electric

Air Pressure : 0.5~0.6MPa

Transport Package : Sea Worthy Wooden Cases

HS Code : 847780000

Machine size of the connected part: 3000 (L) × 1200 (W) × 1800 (H) MM

Power consumption:3KW

Machine parameters :

Machine Details:

Main Features:

1. Automatic tension control of raw materials to ensure balanced raw material tension.

2. Computer program control, high output, good stability and low failure rate.

3, photoelectric detection of raw materials to avoid errors and reduce waste.

4.It can produce one to four layers of mask body.

5. The machine has the function of total count and batch count. The number of batch count can be set arbitrarily.

6. Replacing the mold can produce masks of different sizes and styles.

7, the whole machine adopts aluminum alloy structure, beautiful and sturdy.

Product Features :

1. High stability, low failure rate, beautiful and solid without rust.

2. Computer PLC programming control, servo drive, high degree of automation.

3, photoelectric (optical fiber) detection of raw materials to avoid errors and reduce waste. This machine is a fully automatic production of mask body machine, including automatic raw material delivery; automatic transportation, cutting of the nose bridge strip, mask edge welding, folding, ultrasonic fusion, forming and cutting, etc.

2. Adopt first-line brand ultrasonic welding machine, with high welding efficiency, good quality, stable and durable;

3. High-speed production with a production capacity of 200PSC per minute;

4. Modular design, convenient installation and maintenance;

5. Intelligent control, simple and convenient operation;

6. Automatic shutdown alarm for equipment abnormality, early warning of lack of materials, and intelligent guidance of human-machine interface for quick processing;

7. Appearance is made of food-grade stainless steel.

250pc/min Fully Automated Face Mask Making Machine Mask Production Line

Price Term

1. Price is quoted on EXW based

2. Payment term: 50% down payment, the balance paid before delivery

3. Delivery time: Within 5 workdays after received 50% down payment

4. COUNTRY OF ORIGIN: China

5. MARKING: Notice by buyer

6. PACKING: Wooden Pallet

Product Description : 250PCS / Minute Fully Automated Disposable 3 Ply Flat Earloop Nonwoven Medical Surgical Face Mask Making Machine High Speed Mask Production Line

Machine Description :

The mask making machine is used to fully automated make flat masks with size 175*95mm. The main production process flow is coil material feeding, nose bridge tendon feeding, folding and pressing, mask cutting and forming.Automatically completes production from raw materials to finished masks. The produced masks are comfortable to wear, no pressure, good filtering effect of the masks, fit the human face, and can be used in medical, electronics, mining, construction and other industries.

Basic Info. :

Model NO:MM-L1

Speed :250 PCS/Min

Machine Type:Disposable Nonwoven Machinery

Power Input:110V~380V / 50Hz /60Hz

Product Size :175*95mm

Warranty :12 Months

Service : English Video Call Installation TrainingProduct Type : Mask, Mouth Cover

Usage : Hospital, Public

Weight :600kg

Purpose: Making Disposable Face Mask

Driven Type : Electric

Air Pressure : 0.5~0.6MPa

Transport Package : Sea Worthy Wooden Cases

HS Code : 847780000

Machine size of the connected part: 3000 (L) × 1200 (W) × 1800 (H) MM

Power consumption:3KW

Machine parameters :

| PLC Brand | Mitsubishi / Rexroth |

| Air Pressure | 0.5~0.6Mpa |

| Power supply | 110V~380V 50HZ 60HZ |

| servo motor | Domestic quality |

| Control System | PLC |

| sensor | Omron, Seak |

| Pneumatic Components | SMC Yadek |

| Operation screen | 10 inch capacitive screen |

| Bearing | NSK |

| Lead screw | Hiwin |

| Security | Safety light grid |

| Equipment structure | 2 ply |

| equipment power | 3KW |

| equipment weight | 600KGS |

| Driven | Ordinary motor + servo |

| Number of applicable layers | 3-layer |

| Applicable materials | PP, non-woven fabric, synthetic fiber |

| Processing methods | Ultrasonic welding |

| Finished product specifications | 175*95mm |

| 1. Three layers of fabric are automatically aligned and feed, and weilding sys use ultrasonic waves are continuously pressed. 2. The production line adopts the structure of 2ply, with high production efficiency 3. Nose clips and ear loop are automatically cut and welded by ultrasound | |

Machine Details:

Main Features:

1. Automatic tension control of raw materials to ensure balanced raw material tension.

2. Computer program control, high output, good stability and low failure rate.

3, photoelectric detection of raw materials to avoid errors and reduce waste.

4.It can produce one to four layers of mask body.

5. The machine has the function of total count and batch count. The number of batch count can be set arbitrarily.

6. Replacing the mold can produce masks of different sizes and styles.

7, the whole machine adopts aluminum alloy structure, beautiful and sturdy.

Product Features :

1. High stability, low failure rate, beautiful and solid without rust.

2. Computer PLC programming control, servo drive, high degree of automation.

3, photoelectric (optical fiber) detection of raw materials to avoid errors and reduce waste. This machine is a fully automatic production of mask body machine, including automatic raw material delivery; automatic transportation, cutting of the nose bridge strip, mask edge welding, folding, ultrasonic fusion, forming and cutting, etc.

Advantages :

1. All electrical components of the equipment adopt international first-line brands to ensure the stability of the equipment to the greatest extent;2. Adopt first-line brand ultrasonic welding machine, with high welding efficiency, good quality, stable and durable;

3. High-speed production with a production capacity of 200PSC per minute;

4. Modular design, convenient installation and maintenance;

5. Intelligent control, simple and convenient operation;

6. Automatic shutdown alarm for equipment abnormality, early warning of lack of materials, and intelligent guidance of human-machine interface for quick processing;

7. Appearance is made of food-grade stainless steel.

250pc/min Fully Automated Face Mask Making Machine Mask Production Line

Price Term

1. Price is quoted on EXW based

2. Payment term: 50% down payment, the balance paid before delivery

3. Delivery time: Within 5 workdays after received 50% down payment

4. COUNTRY OF ORIGIN: China

5. MARKING: Notice by buyer

6. PACKING: Wooden Pallet

Product Description : 250PCS / Minute Fully Automated Disposable 3 Ply Flat Earloop Nonwoven Medical Surgical Face Mask Making Machine High Speed Mask Production Line